Our

company possesses one advanced extruder, three eight shuttle looms,30sewing

machines andseveral test equipments. The surface resistance test equipment,

surface break-down voltage test equipment and electricity conducting test

equipment are all imported abroad, which can guarantee quality of every

bulk bag. We also use the metal detector to carry out the final inspection.We

own complete set of production line starting from extruding, circular

weaving, heat cutting, sewing, inspection and pallet packing. We also

insist on the development of new products to ensure that our technology

level is always in thedomestically leading position. Our technologies

ofanti-sift and UV stabilization have passed the tests andare quite stable.

Our company practices the ISO9001:2000 Quality Management System. Our

bulk bags havesafe weight load from 500 kgs ~ 2000 kgs. We made bulk bags

according to customer specification and we also assist our customer to

design bulk bags that are suitable for their needs.

Our

company possesses one advanced extruder, three eight shuttle looms,30sewing

machines andseveral test equipments. The surface resistance test equipment,

surface break-down voltage test equipment and electricity conducting test

equipment are all imported abroad, which can guarantee quality of every

bulk bag. We also use the metal detector to carry out the final inspection.We

own complete set of production line starting from extruding, circular

weaving, heat cutting, sewing, inspection and pallet packing. We also

insist on the development of new products to ensure that our technology

level is always in thedomestically leading position. Our technologies

ofanti-sift and UV stabilization have passed the tests andare quite stable.

Our company practices the ISO9001:2000 Quality Management System. Our

bulk bags havesafe weight load from 500 kgs ~ 2000 kgs. We made bulk bags

according to customer specification and we also assist our customer to

design bulk bags that are suitable for their needs.

Used: Agriculture products, food powder, pharmaceutical

products, chemicals, toner, colouring, construction material, rough gravelStrong

Point: The choice of bulk bag to be used can be influenced by many factors.

We try to offer our clients the most complete solutions to their needs.

The material to be packaged (food, chemicals, abrasives), filling and

emptying methods, transportation method (by land or sea), storing method

(classic, stacking) and other factors must all be taken into consideration.

| Standard Base |

35"

X 35" |

| Height |

40" ~ 75" |

| Capacity |

800 ~ 1200 Liter |

| Max |

1100 lbs ~ 4400 lbs |

| S/F |

5:1 |

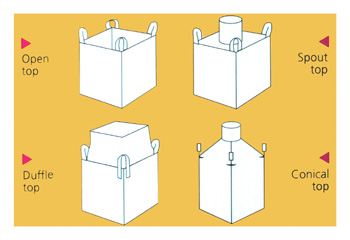

Top Styles

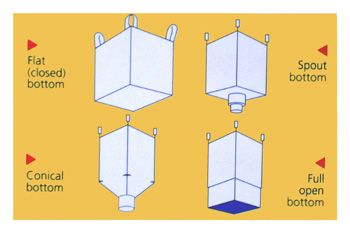

Bottom Styles

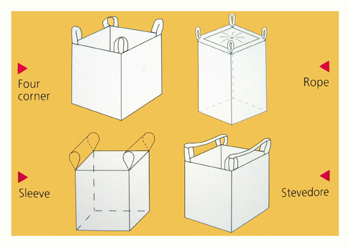

Lifting Styles

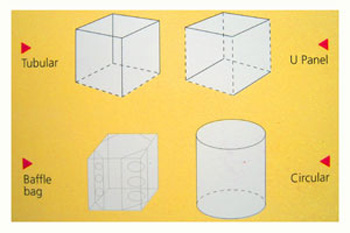

Body Styles

|

|||